Stories: The secret Life of Pasta Technology

Introduction — Before the Technology

Before pasta became dependable, it lived in a world ruled by chance. Wheat fields ripened beautifully across the Mediterranean, but the moment flour met water, everything turned unpredictable. Dough softened and hardened at its own whim. It dried too quickly on some days, too slowly on others, and refused any attempt to store it for long. What cooked well one morning might crack or sour by evening simply because the air shifted.

Even so, people kept returning to wheat. They kneaded it on wooden tables that had been worn smooth by generations, dusted it with flour ground between stones, and shaped what they could in the moment. But everyone sensed the same limitation: this food had no memory. It belonged only to the day it was made.

Yet away from the kitchens, other hands were quietly preparing the ground for a revolution. Millers were adjusting their stones, refining semolina into more even grains. Metalworkers were shaping bronze plates that would later become dies. Carpenters carved wooden screws capable of applying pressure stronger than any human arm. None of them were setting out to “invent pasta,” but each was unknowingly contributing to the machinery that would make pasta possible.

This is where the story begins — not with a grandmother rolling dough, but with a growing realisation that wheat could become a reliable, portable, engineered food. All that was missing was a breakthrough, and it came from the south, carried by the wind that swept across Sicily.

The Arabs and the Sicilian Wind

The Arabs and the Sicilian Wind

When Arab settlers arrived in Sicily in the early Middle Ages, they entered an island shaped by bright heat and constant breeze. The landscape was already rich with durum wheat, a grain harder and more resilient than its northern cousins. The Arabs recognised its potential immediately. They came from lands where drying food was essential, not optional, and Sicily offered them the perfect stage.

On plains near Palermo, they milled durum into semolina, mixed it with water, shaped long strands, and laid them on frames set in the open air. The wind did what kitchens could not: it dried the dough evenly, without splitting or souring. What emerged was firm, durable, and stable enough to travel.

By the mid-12th century, the geographer al-Idrisi described the town of Trabia as a place where dried strands of pasta were produced in such quantity that they were loaded onto ships and sent across the Mediterranean. Sicily had quietly become the first pasta manufacturing centre in Europe.

This was the moment pasta stopped belonging to the day it was made.

It could be preserved, stored, transported — even traded.

It had become a technology.

Everything that followed — the presses, the dies, the factories — grew from the logic established here: wheat could be shaped and made to last if given the right conditions.

Hands, Boards and Blades — The Age of Patience

Hands, Boards and Blades — The Age of Patience

Even after Sicily’s breakthrough, most regions still worked with pasta as a fragile craft. Kitchens across Italy rolled dough by hand, relying on muscle memory rather than measurement. Pasta was shaped according to local customs, influenced by humidity, temperature, and the temperament of the person doing the work.

In a farmhouse in Puglia, orecchiette were pressed under a thumb on a wooden board that had become soft at the edges from years of use. In Liguria, trofie took shape between the palms, spiralling into tight curls. In central Italy, sheets of dough were stretched thin and cut into ribbons that varied with the pressure of a knife.

Drying was uncertain and controlled by weather. A day too warm created brittle sheets. A day too damp yielded soft, sticky failures. Pasta often had to be eaten immediately, not out of preference, but because it could not be kept.

Yet change was happening beyond the kitchen. A miller adjusting a grinding stone created a finer semolina that held water differently. A carpenter carving a wooden screw discovered it could push dough with a pressure no human could exert. A metalworker piercing a bronze plate created the first rudimentary die.

These small innovations hinted at something larger: pasta might not always need to be shaped by hand. It might one day be shaped by machines.

The idea was still a whisper — but the whisper was growing.

Cranks, Screws and Steam — The First Factories

Cranks, Screws and Steam — The First Factories

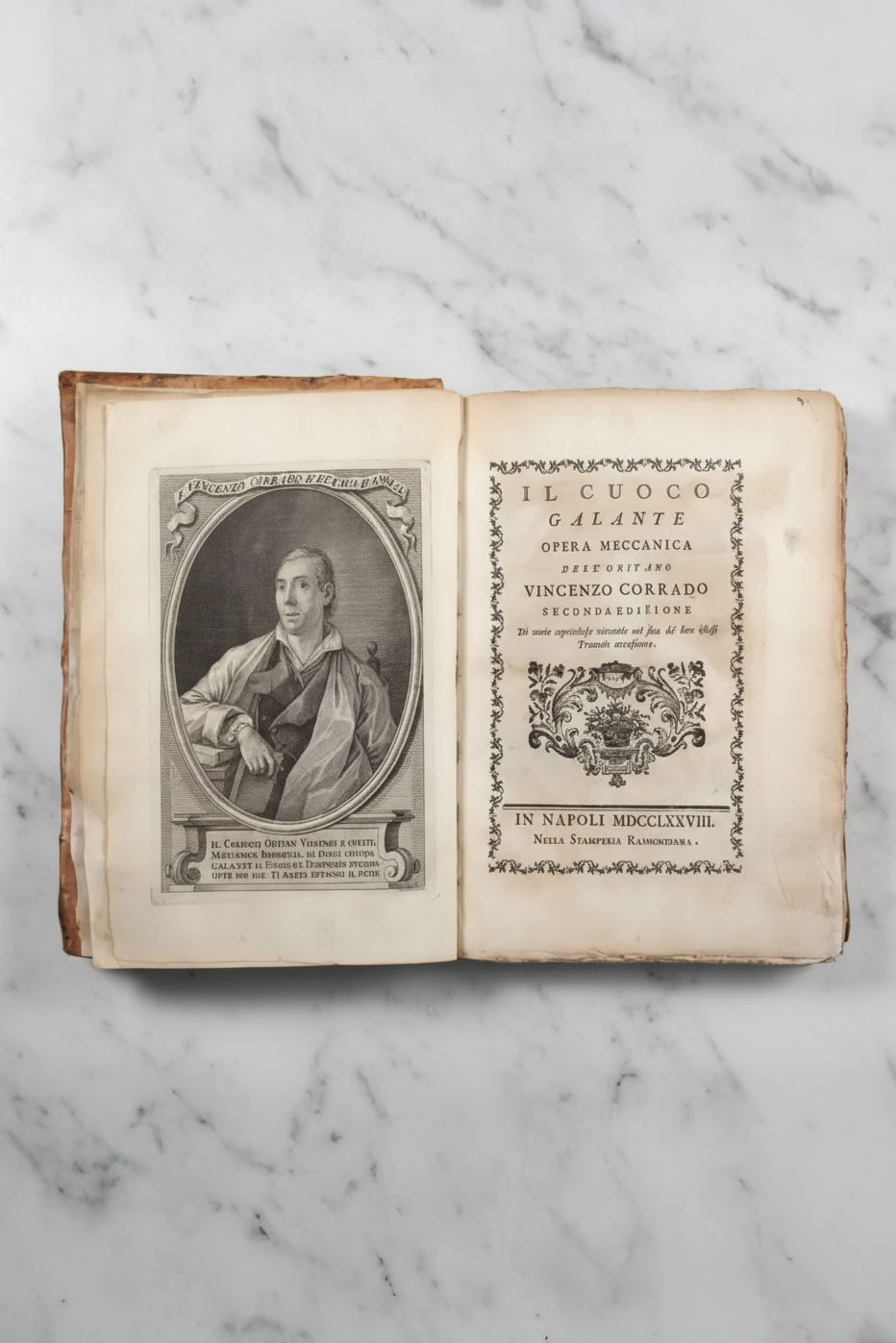

By the 18th and 19th centuries, Italy’s appetite for pasta had grown far beyond what kitchens could produce. Naples, in particular, became a city where pasta was eaten daily, and demand pushed artisans to invent new methods.

The first pasta factories were surprisingly modest places. Wooden screw presses stood at the centre of the room, operated by workers who turned cranks to push dough through bronze plates. The pressure forced the dough into new shapes: tubes, ridges, and strands that no longer depended on the precision of a knife.

These presses brought two important changes. First, they increased uniformity — a crucial factor for drying and cooking. Second, they shifted pasta from the pace of the household to the pace of the city.

Soon, steam engines replaced human effort. Hydraulic systems applied steady, powerful pressure. Dough flowed through dies more consistently, and shapes became regular enough for drying to be predictable. Long drying racks were built in heated rooms, where workers monitored airflow and temperature by feel: opening shutters, adjusting vents, raising or lowering racks.

This was the beginning of industrial pasta.

Not yet modern, but no longer bound to the rhythms of weather.

The Birth of Extrusion — When Pasta Became a Flow

The early 20th century brought the most decisive shift in pasta history: continuous extrusion.

Instead of pressing dough in batches, factories began using rotating metal screws housed inside cylinders. Dough was mixed, compressed, and pushed forward in an unbroken stream, passing through dies with relentless consistency.

For the first time, pasta became a flow rather than an event.

Spaghetti emerged as endless ribbons. Tubes appeared at exact lengths, cut cleanly as they left the die. Shapes that required complex internal structures — fusilli, penne, conchiglie — became not only possible but reliable.

Extrusion changed pasta on a molecular level. The intense pressure aligned gluten networks, strengthening the dough and giving cooked pasta its distinctive bite. The surface became smoother and more uniform, ready to evolve into two distinct paths depending on the material of the die.

Machines now shaped pasta with a precision that hands could not achieve. The pastas of Italy’s future were being born.

Bronze and Teflon — A Question of Surface

Bronze and Teflon — A Question of Surface

For centuries, pasta had emerged through bronze dies. Bronze gave dough a matte surface, slightly rough to the touch, with tiny pores that absorbed sauce beautifully.

Then, in the mid-20th century, a new material arrived: Teflon.

Factories experimented with lining dies in Teflon and discovered significant advantages:

- Dough slid through more easily.

- Dies lasted longer.

- Production speeds increased dramatically.

But Teflon created a flawless, glossy surface that changed pasta’s relationship with sauce. Where bronze offered grip, Teflon offered elegance — a polished texture that some found attractive but others found too smooth.

This introduced a quiet divide in the pasta world.

Bronze die pasta carried the rustic character of tradition.

Teflon die pasta represented efficiency and the uniformity of modern industry.

Both had their place.

Both still do.

The choice of die material became not just technical but philosophical:

Was pasta meant to cling to sauce, or glide beneath it?

Drying 1.0 — The Slow Art of Patience

Drying 1.0 — The Slow Art of Patience

Even as shaping improved, drying remained one of the most unpredictable parts of pasta making. Until the 1970s, drying was a slow conversation between human intuition and the weather, even inside factories.

Pasta was arranged on wooden frames and moved between heated rooms. Workers watched carefully for signs of stress: tiny cracks forming on the surface, a softening of the interior, an uneven change in colour. They adjusted airflow, opened or closed vents, and shifted racks to prevent disaster.

Every shape had its own sensitivity. Long cuts needed time to stretch and settle. Short shapes needed more movement of air around their sides. Filled pastas were especially fragile.

Drying was long and labour-intensive, often taking more than a day. But this slow pace helped preserve the subtle aroma of semolina and created textures many Italians still consider the gold standard.

Yet demand kept growing, and this gentle approach could not sustain larger production. Factories needed a faster, more reliable method.

Drying 2.0 — The High-Temperature Era

Drying 2.0 — The High-Temperature Era

In the 1970s, pasta drying underwent the most profound transformation since the Arab era.

Engineers learned that drying at higher temperatures — sometimes approaching 90°C — reduced total drying time dramatically and improved the firmness of cooked pasta. This new method required precise control: pasta moved through a sequence of chambers, each with its own temperature, humidity, and airflow, carefully programmed to prevent cracking or collapse.

Drying was no longer guided by instinct.

It became the domain of thermodynamics.

High-temperature drying created pasta that held its shape during cooking, resisted overcooking, and could be produced in far greater quantities. It gave pasta the firmness associated with modern “al dente.”

Not everyone embraced it.

Some producers preserved slower, low-temperature methods to retain flavour nuances. But industrial producers adopted high-temperature drying widely, making pasta more consistent and more stable than ever before.

Vacuum, Kneading and Microbiology — Perfecting the Interior

Vacuum, Kneading and Microbiology — Perfecting the Interior

With shaping and drying refined, attention turned inward: the structure of the dough itself.

Vacuum mixing and kneading emerged as crucial innovations. By removing air during the mixing process, factories eliminated tiny bubbles that would otherwise weaken the pasta during drying or cooking. Cross-sections became clean, smooth, and uniform.

Steam treatments and pasteurisation opened the door for fresh and filled pastas to become widespread, allowing them to travel and shelf-stabilise in ways never possible before. Dough sheeting machines created ravioli and tagliatelle with millimetre-level precision, guaranteeing even cooking.

In this period, pasta began behaving less like a handmade craft and more like a carefully engineered material. Every stage — mixing, kneading, shaping, drying — contributed to a final product designed to cook exactly the same way every time.

Continuous Lines and Automation — The Age of Precision

Continuous Lines and Automation — The Age of Precision

By the late 20th century, pasta factories transformed from noisy, labour-intensive spaces into controlled, quiet environments where machines performed the choreography.

Continuous lines emerged: long, gleaming sequences of mixers, extruders, conveyors, dryers and coolers that moved dough seamlessly from one stage to the next. Workers became operators and supervisors, monitoring screens instead of racks.

Sensors measured moisture, temperature, and colour in real time. Software adjusted drying curves automatically. Machines adapted to the changing characteristics of semolina from different harvests.

Pasta had become a predictable, reliably engineered food. Every piece that emerged from the line carried the same weight, the same density, the same behaviour in boiling water.

The factories no longer looked like the sun-filled courtyards of Trabia or the wooden rooms of early Naples. But the lineage remained: the same wheat, the same water, refined through centuries of invention.

The Future — New Grains, New Materials, New Logic

The Future — New Grains, New Materials, New Logic

Today, pasta enters a new phase shaped by new challenges.

Gluten-free and alternative-grain pastas require different pressures, binders and drying rhythms. Die manufacturers experiment with hybrid materials and micro-texturing to replicate the tactile benefits of bronze while maintaining the efficiency of modern synthetics.

Artificial intelligence assists in creating optimal drying curves based on batch conditions, reducing waste and energy consumption. Sustainability efforts push factories toward heat-recovery systems, improved insulation, and water-efficient mixing processes.

The technological landscape continues to evolve, but the core question remains the same:

How can wheat — or chickpeas, or rice, or corn — be shaped, dried, and preserved so that it nourishes people reliably, wherever they live?

This question has motivated every innovation from the Arab drying racks to the most advanced extrusion lines of today.

Conclusion — The Long Engineering of a Simple Food

Pasta may appear simple, but its history is anything but. It is the product of a thousand years of refinement — a collaboration between climate, craft, engineering and imagination.

From the hot winds of Sicily to the wooden screw presses of Naples, from bronze dies to Teflon, from slow drying rooms to high-temperature tunnels, every step shaped the pasta we now take for granted. The firmness of a rigatoni, the curve of a fusillo, the bite of a perfectly cooked linguine — all are the outcome of countless hands and machines overcoming the limitations of wheat.

What we eat today is not just a food.

It is the result of problem-solving across generations.

Pasta is tradition, yes — but it is also technology, quietly perfected over centuries.

Fun Facts — Small Windows into a Big History

Fun Facts — Small Windows into a Big History

-

Sicily’s first dried pasta travelled by sea.

By the 1100s, dried strands from Trabia were shipped across the Mediterranean as a reliable trade item. -

Durum wheat is chosen for physics, not nostalgia.

Its hard grain structure is uniquely suited to withstand extrusion pressure and intense drying. -

Bronze dies were practical before they were poetic.

Their famous rough texture was originally a by-product of the material, not a design choice. -

Teflon dies helped machines more than pasta.

They reduced friction, increased speed and extended die life; the glossy surface was a side effect. -

Drying determines more than taste.

Two pastas made from identical semolina can behave completely differently depending on the drying curve applied. -

Extrusion pressure can exceed 100 bar.

This aligns gluten in a way impossible by hand, giving pasta its signature bite. -

Early factories relied on weather like sailors.

A storm or humidity spike could ruin entire batches in the pre-controlled-drying era. -

Continuous pasta lines were inspired by textile machinery.

The logic of drawing threads through controlled environments migrated from fabric to food. -

‘Al dente’ is partly the invention of modern drying.

Earlier, softer pastas often cooked differently; the firm bite we know today is shaped by technology. -

Every pasta shape exists because a die allowed it.

Even traditional shapes gained their modern identities only once machines could reproduce them consistently.